Product Description

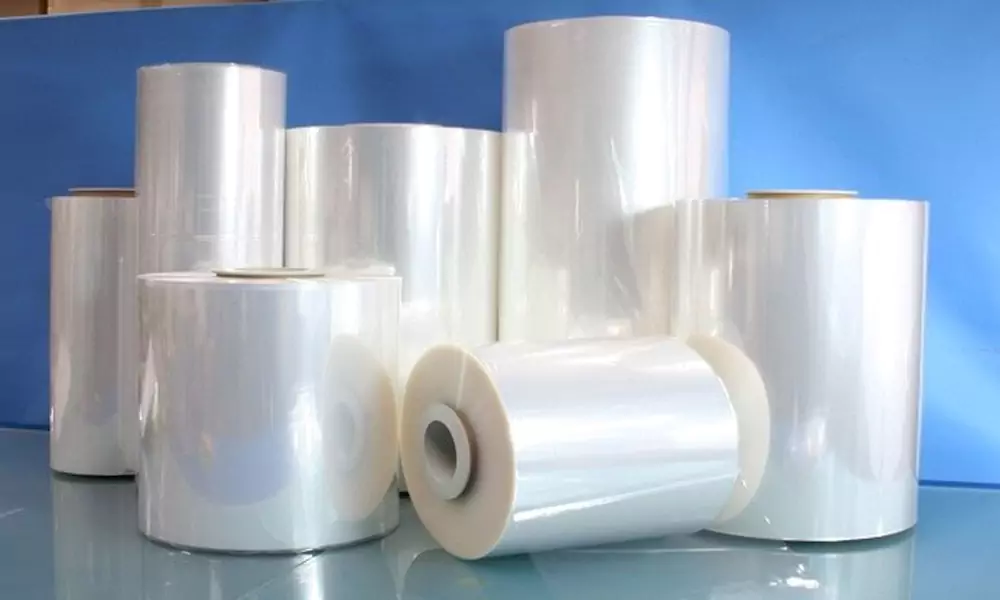

As the demand for various products rises, there's a growing need for standardized and practical solutions. Among the most valuable assets in this regard is polyolefin shrink film, commonly known a POF, which has proven to be indispensable for many users in recent years.

These films belong to the category of plastic sheets used for packaging consumables, making them crucial in terms of logistics. You've likely noticed the use of plastic layers around food product boxes, engine oil containers, and similar items. These layers are essentially polyolefin shrink film in action.

Getting to know Polyolefin Shrink Films

Polyolefin shrink film serves as a versatile packaging solution for a range of items, including food, paper goods, pharmaceuticals, and electronics. It's crucial to protect these items from potential damage, such as humidity, and the unique properties of polyolefin films make them suitable for such purposes.

The significant advantages of these films are

The four main advantages of polyolefin shrink film, which have resulted in the increasing popularity of these products day by day, are excellent resistance to humidity, exceptional flexibility, surface transparency, and improved packaging efficiency. In addition to these items, we can also refer to additional options like low prices, which are a major factor in choosing the user.

Moisture Resistance

Polyolefin shrink film's resistance to moisture is invaluable, particularly when packaging products for unfavorable environments. This property ensures the integrity of the packaged items during transportation.

Great elasticity

While all shear films possess elasticity to some extent, the degree and scope of this characteristic vary among them. Typically, the greater the elasticity of a sheet, the more convenient it is for tasks such as packaging. Polyolefin shear films stand out for their exceptional elasticity compared to other products in this domain. It's worth noting that these sheets also excel in terms of shrinkage, promising a pleasant surprise.

Surface Transparency

Polyolefin shrink film boasts clarity on its surface, allowing consumers to scrutinize package contents meticulously. Through this transparency, essential details like the production and expiration dates of enclosed food items become readily visible. Despite their see-through nature, polyolefin films defy misconceptions of fragility. These tapes exhibit robustness, resisting tearing and damage with ease. Such attributes collectively endorse the use of products that prioritize hygiene, standardization, and practicality.

Acceleration of the Packaging Process

Utilizing polyolefin shrink film requires the application of heat for shrinkage, which can be achieved through semi-automatic or fully automatic methods. Regardless of the chosen method, both options outperform traditional packaging processes involving plastic sheets in terms of speed. By expediting the packaging process, businesses can increase product delivery to consumers, resulting in long-term profitability.

Selecting the Best Polyolefin Shrink Film

Tailored polyolefin shrink films, formulated with specialized structures, have transformed the packaging of various products. The utilization process involves simple steps of heating and cooling. When selecting these films, it's essential to prioritize options with high durability and strength. For those seeking premium-quality polyolefin shrink film at competitive prices, Hayat Plastic Asia offers comprehensive solutions. Our services are readily available to meet your needs anytime, anywhere.

fa

fa en

en